For those who has suspension failures – don’t panic – it’s not hard to identify the real problems and don’t expect the dealers or independent shops to find the problems for you. They will recommend to replace parts until it’s found on your expense. I summarize the trouble spots on low down suspension – Many people would replace the air pump first without thinking… because it doesn’t pump when the ignition is turned on – to be sure is to connect direct 12V to the unit to verify.

Before assuming which part of the system is bad, should do some simple tests first:

- Take the car home – use a charger to charge the battery because the pump will draw lot of current or turn on the engine while doing this.

- Go to MMI and set to LIFT as soon as the ignition is turned on.

- Wait for the pump to finish pumping the car to the mode (highest), when it stops pumping and the car is in LIFT mode, select car-setup to set to – remember , therefore you’ll never hear the pump pumping. Most people forgot to turn off the JACK-MODE and thought their pumps are DEAD.

- When the car is in LIFT and JACK mode – wait for a few hours, the leaky air shock will be lowered or if the whole front or rear are lowered then it’s may well be the Valve Block.

- If the air pump is dead – yes, it can’t pump air but don’t go there yet.

- Check the fuse and the relay 367 under the dash on the driver side (left) – if the relay is bad, the pump will keep running until the battery runs out even the engine is turned off.

- If there’s a leak on one of the strut – the suspension level sensor will lower the good strut to be the same height as the leaky one, hence all corners are low. Don’t assume any strut until the soap water test is performed.

- If one strut doesn’t go low while other do, .

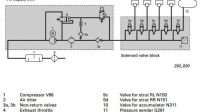

- The air valve block is known to leak if the block is corroded and the .

- If the strut leaks on the bottom of the air spring bag, the O-ring there may be bad – you can try to replace the O-ring before doing anything else and save you tons of work and money.

- If the suspension sit high, never goes lower – Check the and the valve block. The pump should be the defective component.

- If your suspension is GOOD, just the air spring bag is leaking, don’t buy the rebuilt one, because you don’t know if the struts on those are good. Try to keep your original strut. 2 components are totally independent: air bag and strut, the strut has electrical wires that control the stiffness of the ride.

03/24/2017 Tstealth32 in Audiworld forum replaced the big O-ring and it seemed to fix the air leaks on the bottom – it’s $1 O-ring – not proven working.

The size should be a little over 1.5″ in diameter for the big one and 3/8″ for the small one. The thickness should be 1/16″ or 3/32″.

What’s made can fail, will fail… My 2006 A8L air suspension failed last weekend @ 119k miles. The front drops down like a low rider or a race car. I could drive 60 miles from the time it failed to home @ 60-75 MPH on California Freeways 101 and 880 without any problem but a little bouncy over uneven surfaces. I’m going to find the problem when I have time, this weekend?

Ordered an and it came in 3 days assembled with dust cover.

Finding the problem

Iloveandhateaudis actually had the and with a few 25 cents O-rings, he fixed the suspension… Amazing.

If the leaks is identified as coming from the bottom of the strut, try to replace the O-ring and put some PCV glue around the bottom, wait for it to dry and test it. You may fix the leaking strut easily. You don’t need to remove the whole strut, just remove the fork out of the control arm, pry up the air spring sleeve to expose the o-ring, replace it, and put the sleeve back down…

Make sure to support the Brake Spindle when the strut is removed or the spindle will fall and break the outer CV boot, more work created…

For the people who don’t want to cut the wire, need to remove the pins out of the connector.

**** Many people replace the bags and it leaks or blown up in a few days or clunking sound appears on the strut – These things must be implemented very carefully ****

1. There are 2 rubber rings, small and big, these must be lubricated with grease or oil, I used Mobil 1 oil – they must be fitted in the groove prior to strut installation with the air bag.

2. There is a bushing inside the new air bag already, make sure it’s the same height and width like the original, the clunking may cause by this bushing. Do not install the old one on top of the new one, only 1 needed.

3. Push the Piston (long metal case) all the way down to the shock stopper and make sure the inside are clean, especially where the big O ring is. While doing this, make sure it doesn’t push the O-ring out of place. When it’s done, pull the sleeve over and lock it over the shock.

4. When the suspension is still in lift and jack mode and jacked up, turn on the ignition for the pump to pump air into the air bag to achieve at least 3.5 bar = 50 PSI before putting pressure on the suspension by lowering it down.

5. After finishing the strut installation to the car, do the height adjustment before putting the tire back on to preserve the UPPER CONTROL ARMS from over extended. If you release the air to do this, make sure to turn on the ignition for the pump to pump the air back in again.

23 Comments

Hi, I continue to have a problem with one side lower than the other. It appears pump works and I do not detect any leaks. Thinking something has gone wrong with the leveling sensors. Do you have a clear picture of exactly where they are on the front? I enjoy your videos and they have helped me save some time doing my own A8L work over the years. By the way, I have replaced both air shocks within the last 3years. Hope to hear from you. Thanks